Seaworthy Packaging

“4-Time WORLDSTAR Award-Winner Suprabha Seaworthy Packaging System”

India is emerging as the world’s largest and most preferred resource for machined components. In order to meet the exact requirements of exporters of engineering goods, Suprabha has indigenously developed packaging systems that ensure that machined components reach their destination free from rust and corrosion.

Conventional Methods and their drawbacks :

Conventional packing materials like wood, polythene sheets or shrouds, silica gel, bitumen paper or jute cloth may normally be adequate for packing, but not for engineering items where quality demands are high. Exporters of engineering goods often experience problems of corrosion, after having used conventional packing.

What is worse is that at times, conventional materials are the cause rather than the antidote to corrosion.

- Unseasoned wood releases acetic/formic acid fumes under hot and humid conditions, typically during sea voyages and rains. These acidic vapours spread inside the packing, leading to corrosion. Wet wood is also susceptible to the growth of fungus and vermin.

- Polythene sheet shrouds made of LDPE are used for their water-repellent properties. However, these very shrouds transmit moisture into the pack by transgression. Diurnal changes in temperature further promote recurring cycles of condensation and evaporation within the pack, due to what is known as the ‘breathing phenomenon’ of LDPE. The thinner the gauge of the film, the greater is the transmission. While a thicker gauge of LDPE film is safer, transmission cannot be completely ruled out. LDPE film is often made from recycled material, and may contain impurities that drag in and damage packed components. Virgin quality material can be used safely, although it means a significant rise in cost.

- Bituminised jute cloth tears easily during transit, making it inappropriate barrier material for packing engineering components or machinery. The torn areas allow moisture and other pollutants to seep in and corrode the sensitive cargo. Further, at temperatures above 40°C, the tar coating of the cloth melts, seeping through the punctured areas and getting deposited on packed components. Cumulatively, these factors can cause expensive damage to the packed items.Another significant risk of using jute is its vulnerability to fungal attacks. This happens since jute is created with organic fibres, which tend to retain moisture for long periods of time.

- Silica Gel is commonly used as a desiccant. However, in its commonly available form, this material is incapable of absorbing more moisture than 25% of its own weight. Any excess moisture in the packaging environment remains unabsorbed; this settles on components and corrodes them. To make matters worse, as temperatures rise, silica gel releases the absorbed moisture back into the environment, further increasing humidity to dangerous levels. Further, the acidic nature of silica gel renders the trapped moisture acidic, which then is cyclically vapourised and condensed with day/night temperature variations.The result is evident in heavy corrosion of machined components as also plated components. Painted surfaces too develop blisters. Corrosion is more evident in places where a silica gel pouch comes in contact with a metal surface. Safer options are to heat silica gel in an oven to 150oC before use, or to adopt vacuum packing, but both options are impractical for a number of reasons.

Rust Prevention…the Suprabha approach :

With its decades of experience and R&D efforts, Suprabha has achieved dramatic results in controlling the phenomenon of corrosion.

The group has developed SO VCI® (Suprabha’s Organic Vapour Corrosion Inhibitors), a family of organic chemicals, which emit vapours that are attracted towards metal surfaces. These vapours migrate, condensate and form a monomolecular film on metal surfaces, even recessed ones like bores and cavities. The film forms an effective barrier between the metal surface and corrosion-causing agents in the atmosphere.

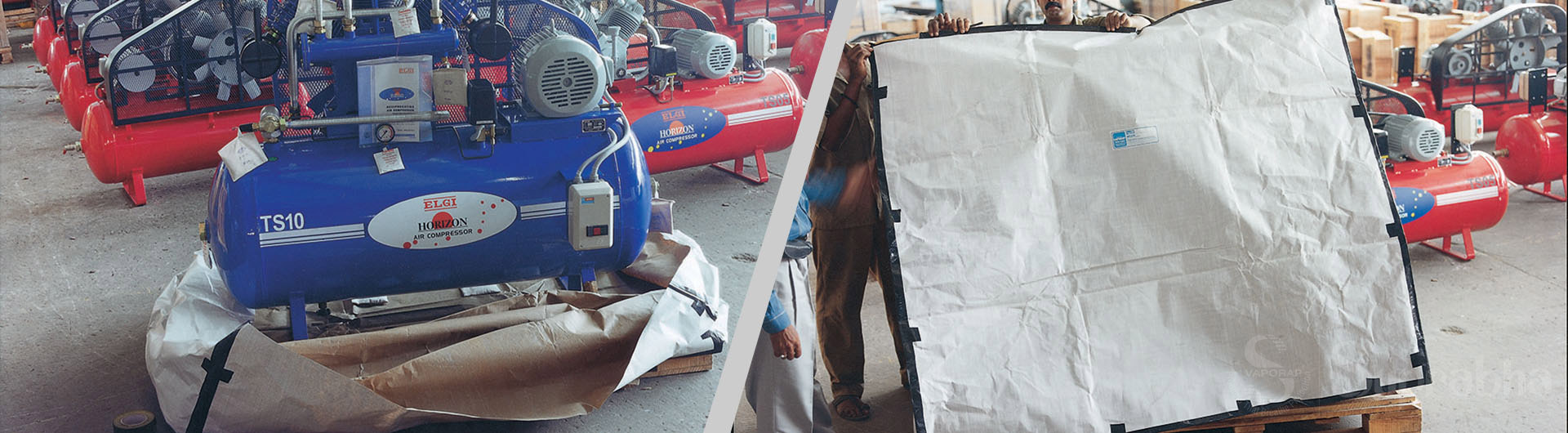

Keeping the needs of exporters, especially those in the engineering industry in mind, Suprabha has partnered with packaging experts to develop a range of packaging material and rust preventive oils, water based liquids, gels, powders and tablets. The Suprabha Seaworthy Packaging System consists of covers fabricated from multi-layered paper, SO VCI® Powder, Dehumidifier and R.P oils which can withstand not only exhaustive of sea voyages but also the handling during transit.

The barrier material (Rustopaper) is a multi-layered paper of LDPE film, HDPE woven fabric, LDPE film and SO VCI® impregnated paper inside, bound together through a superior lamination process. Rustopaper is 100% waterproof, with excellent barrier properties and the ability to prevent moisture transmission. It has good wear and tear strength and its HDPE fibre keeps packed material free of fungal and termite attacks. Covers or bags of any size can be fabricated from this paper, either as flap type cover or as a hood and bottom sheet type in case of bigger machines, which are mounted on base pallates. The chemical impregnation to the paper conforms to IS-6263 specifications. This single material substitutes all the other materials such as tar coated paper, jute cloth and polythene cover. In situations where machines are loaded in containers at the factory, expenses incurred in wooden packing and crates can be reduced.

To supplement the chemical requirement inside the pack, SO VCI® Rustopowder is used in combination with our specially developed Suprabha Dehumidifier. These condition the atmosphere within the box. SO VCI® Rustopowder, which conforms to IS-5730, is non-hygroscopic in nature and sparingly soluble in water; hence unlike silica gel, it does not cause corrosion, even where it is in contact with the metal surface.

Suprabha Dehumidifier is designed for use as a desiccant. A combination of activated metal compounds like lavigated alumina and bentonite, this product absorbs moisture but does not release it back into the environment, even during normal cyclic temperature variations. Its pH value is near neutral, and hence does not cause any corrosion to the packed metal. Suprabha Dehumidifier is non-toxic, pollution-free and environment-friendly, and can be disposed of as a solid waste without any special treatment.

Apart from packing materials, Suprabha has developed an inexpensive water-based wood protective liquid to safeguard wooden packages/boxes from fungus and termite attacks. The product used is safe to use and environment-friendly, unlike the harsh wood treatment using MB (Methyl Bromide) solutions.

How the system works :

The superior barrier properties of Rustopaper prevent the entry of moisture or gases which can damage packed material. The bags are fabricated using laminated HDPE fabric adhesive tapes, which avoids any ingress from outside or leakage of SO VCI® vapours from inside through the joints.

Inside the pack, SO VCI® chemicals take immediate effect. The entrapped atmospheric moisture is saturated with SO VCI® molecules, rendering it non-corrosive. The monomolecular protective barrier created on every metal surface and recessed area by SO VCI® prevents direct contact with moisture molecules. In the process, they build up a slightly higher vapour pressure than the atmospheric pressure. Once this pressure is attained, vaporisation automatically ceases. It restarts if there is a loss in the pressure due to a leak, opening of the pack tearing of the Rustopaper bag while handling. The system is self-replenishing as long as Rustopowder remains inside the bag. An added advantage is that under normal circumstances, there is no possibility of any ingress due to the higher pressure within the box.

This system is effective thanks to the superior packaging material outside and the suitable conditioning of the atmosphere inside the packaging.

To sum up, the advantages of Suprabha Seaworthy Packaging are:

- Superior protection: to metal components through a holistic approach.

- Optimisation of packaging material: A reduced volume of packaging material required as pouches, shrouds or bags can be made to size/shape.

- Ready-to-use delivery: Components reach their destination ready for assembly – there’s no need to de-oil or de-grease surfaces.

- Environment-friendly: Materials used are easily disposable and non-toxic.

Suprabha Seaworthy Packaging Systems for bulk packing of components :

Suprabha Seaworthy Packaging System uses a series of innovations to protect precious shipments.

Operating at two levels of protection, this solution provides a superior barrier material on the outside, while conditioning the entrapped atmosphere inside the packing. This system uses the inherent strength of Suprabha’s Organic Vapour Corrosion Inhibitors (SO VCI®) in the form of packing material, rust-preventive oils, water-based liquids, gels, desiccants and tablets, to ensure corrosion-free delivery of high-value engineering components to overseas destinations. Exporters benefit from :

- Economical and effective packaging in any shape or size.

- Airtight and waterproof protection that is effective from 6 months to 1 year.

- Savings by eliminating the need for vacuum packaging.

- Potential of reuse and recycling.